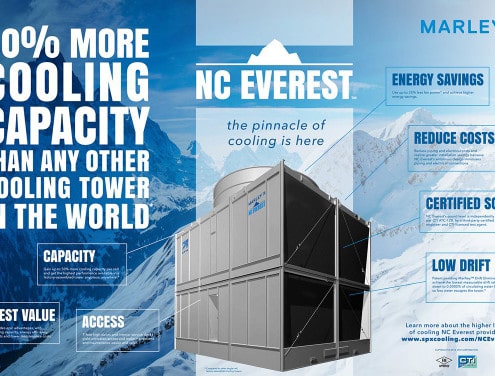

SPX Cooling Technologies embarked on a mission to design and build a cooling tower like no other in the world. Like adventurers climbing Mt. Everest, we knew the challenges yet were driven to achieve something remarkable. We forged a path to the summit that takes cooling to a higher level. The result, the NC® Everest TM, provides epic customer advantages, with up to 50% greater cooling capacity, higher energy savings, fewer components and lower maintenance costs. Compared to other factory-assembled towers, NC Everest rises above the rest.

Features

The NC Everest includes additional advantages that distinguish it as a member of the Marley NC Cooling Tower Series:

ROBUST DESIGN AND MATERIALS

- Heavy gauge steel structure, galvanized or stainless steel

- 5-year mechanical component warranty

- Rugged genuine Marley Geareducer® drive

- Energy-efficient PVC heat exchange fill media

- Integral louvers and drift eliminators

CERTIFIED THERMAL PERFORMANCE

- Certified by the Cooling Technology Institute to meet thermal performance as specified.

FACTORY MUTUAL APPROVED

- FM approved for use without a fire protection system to allow more affordable operation insurance

OPERATIONAL ADVANTAGES

- Less sunlight exposure for reduced water treatment requirements

- Reliable cold weather operation from crossflow design

- Variable flow water distribution system for improved energy efficiency in off-peak loads

HVAC and Light Industrial applications

Compared to other single-cell, factory-assembled cooling towers, NC Everest offers monumental advantages for HVAC and Light Industrial applications:

- Up to 50% greater cooling capacity than any other cooling tower in the world

- Higher energy savings with up to 35% less fan power

- Reduced piping and electrical connections for greater installation savings

- Unrivaled interior access for easier and safer inspections and maintenance

Heavy Industrial and Power applications

Compared to field-erected towers, NC Everest offers dramatic advantages for Heavy Industrial and Power applications:

- Up to 50% more cooling capacity than any other pre-assembled cooling tower in the world

- Up to 60% faster delivery

- Up to 80% faster installation

- More site flexibility and safer assembly process

- No costly concrete basin construction required

- Higher energy savings with up to 20% reduction in pump energy

- Lowest drift rate, down to 0.0005% of circulating water flow