Marley Air Cooled Condensers – Dry Cooling

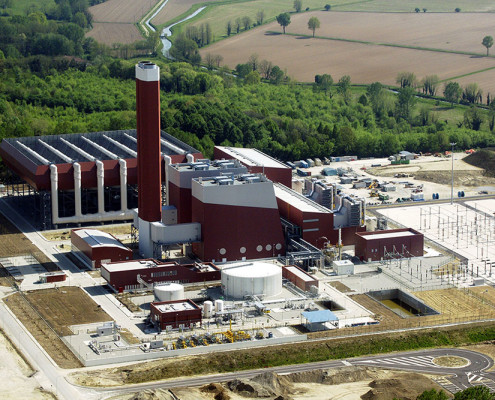

Air Cooled Condensers directly condense exhaust steam from the steam turbine and return condensate to the boiler without water loss. They are frequently used in electrical power plants and waste to energy plants of all sizes.

Features

An Air Cooled Condenser (ACC) is a direct dry cooling system where the steam is condensed inside air-cooled finned tubes. Since there is no intermediate surface condenser like Indirect Dry Cooling, the overall performances is better.

The SPX Air Cooled Condenser features long-term mechanical and thermal integrity, excellent corrosion and freeze resistance, low fan power consumption, reliable operation and low maintenance.

An Air Cooled Condenser (ACC) is made of modules arranged in parallel rows. Each module contains a number of fin tube bundles. An axial flow, forced-draft fan located in each module forces the cooling air across the heat exchange area of the fin tubes.

The typical scope for an ACC installation includes the supporting structure, the steam ducting from the steam turbine interface, auxiliaries such as the condensate and drain pumps, condensate and duct drain tanks, the air evacuation units and related piping works and instrumentation.

The Fin Tube is the core technology of the Air Cooled Condenser.

- Single-Row Condensers (SRC®) – an elongated, flat tube with brazed aluminum fins.

- Multi-Row Galvanized (MRC) – an oval tube with hot-dip galvanized steel fins.

The major benefits of Dry Cooling are:

- Elimination of additional water usage from the condensing power cycle

- Flexibility in power plant site selection

- Decreased time required for plant permitting

The most popular style of Air Cooled Condenser is the modularized A-Frame design, used on power plants of all sizes.

SPX developed the Hexacool ® Air Cooled Condenser (ACC) for use in smaller waste to energy, biomass and small size electrical power plants and industrial co-generation.